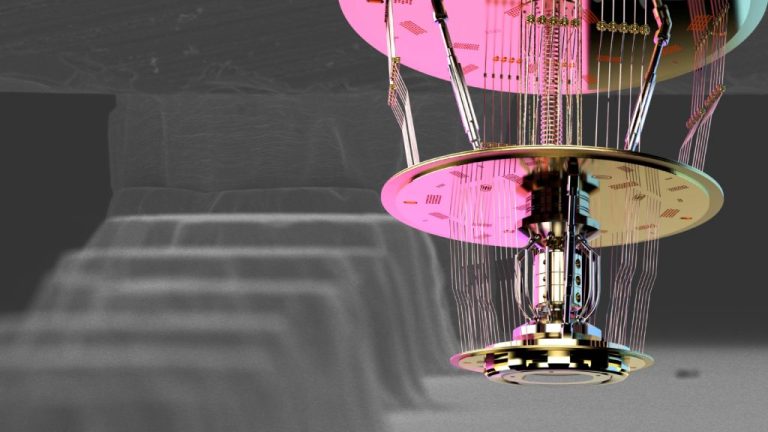

- Ultra-precise 3D integration of superconducting qubits with sub-micron bonding accuracy

- Precise, cryo-stable processes needed for scalable, fault-tolerant quantum chips

- Cost-efficient quantum architecture ready for real-world use

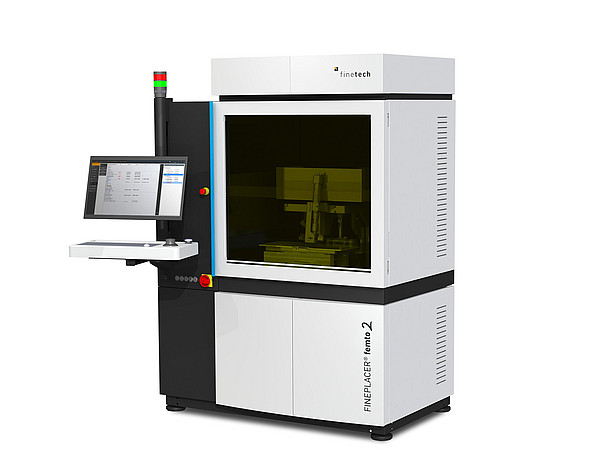

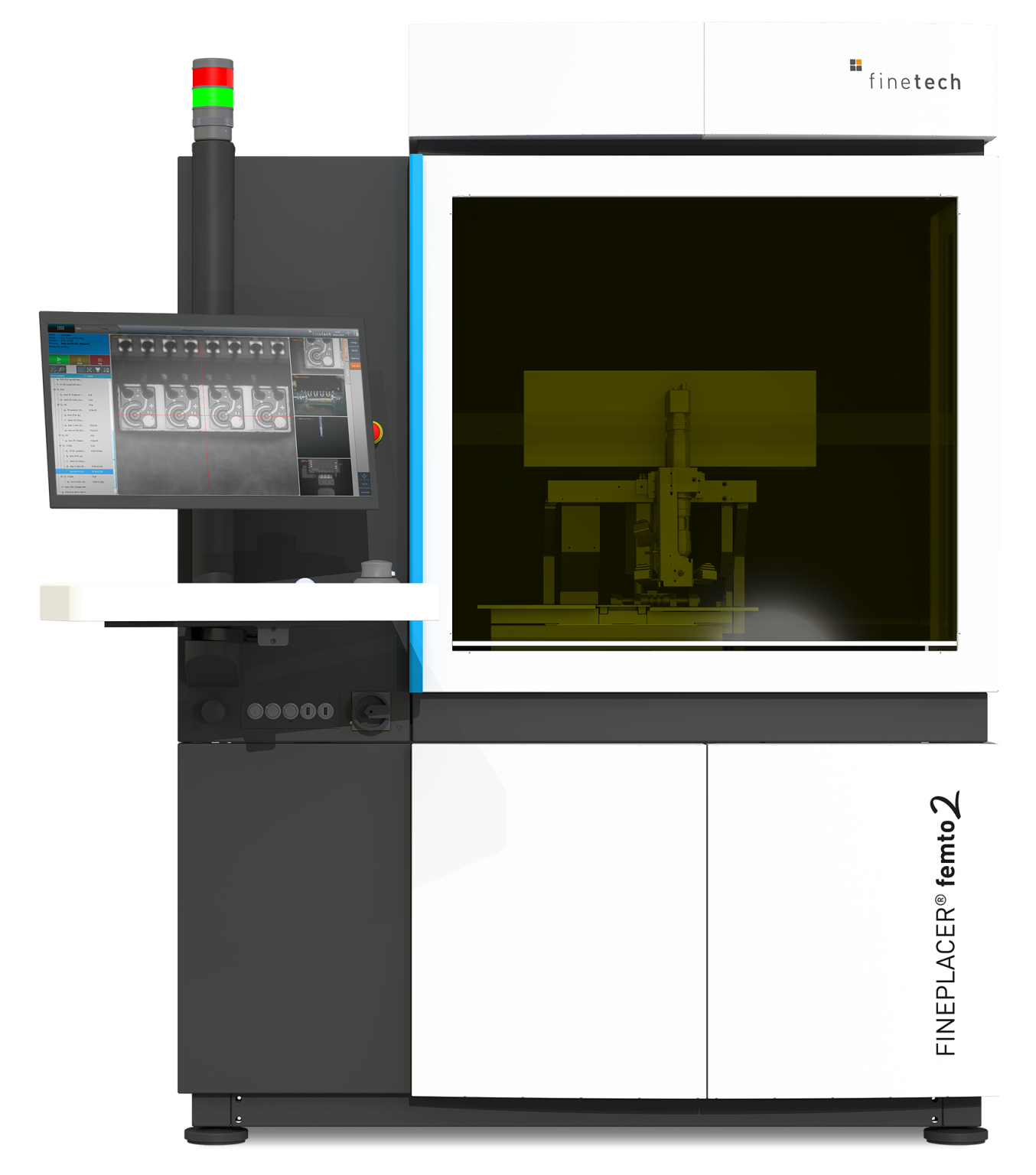

Munich-based Peak Quantum develops high-coherence superconducting quantum processors designed for fault-tolerant computing at scale. For qubit integration, the company relies on Finetech’s Indium Bump Interconnect (IBI) bonding and the sub-micron accuracy of the FINEPLACER® femto 2 die bonder.

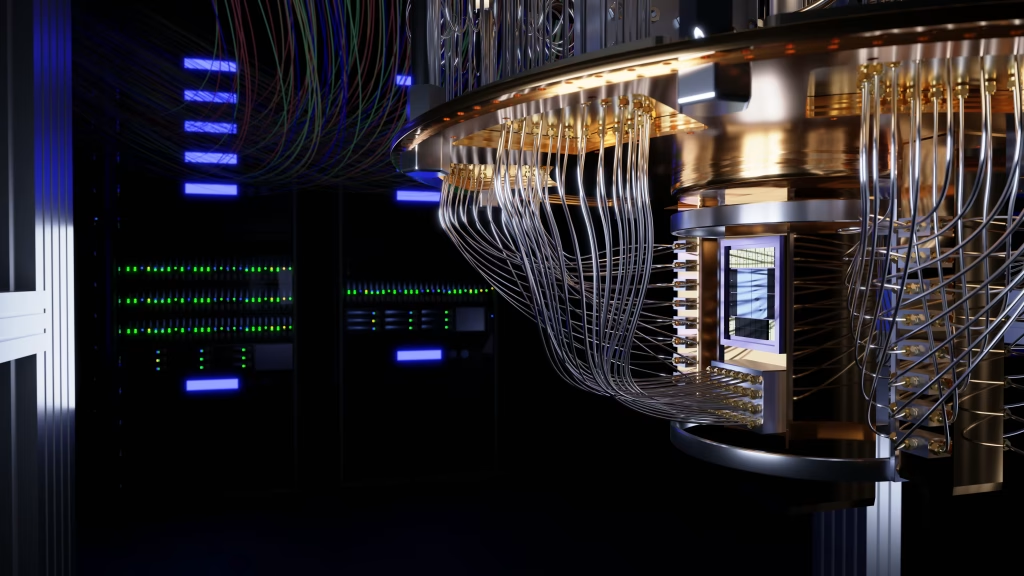

Fast track to industrial quantum computing

Peak Quantum provides scalable QPUs with a unique architecture that requires an order of magnitude fewer physical qubits and embeds error protection at the hardware level. This makes quantum systems more cost-efficient, more reliable, and significantly more powerful.

The company’s goal: accelerate quantum hardware for high-performance computing to tackle real-world challenges in chemistry, logistics, and other complex problems beyond classical reach.

By using this element, you agree that your data will be transmitted to external services (https://www.youtube-nocookie.com) and that you have read our privacy policy.

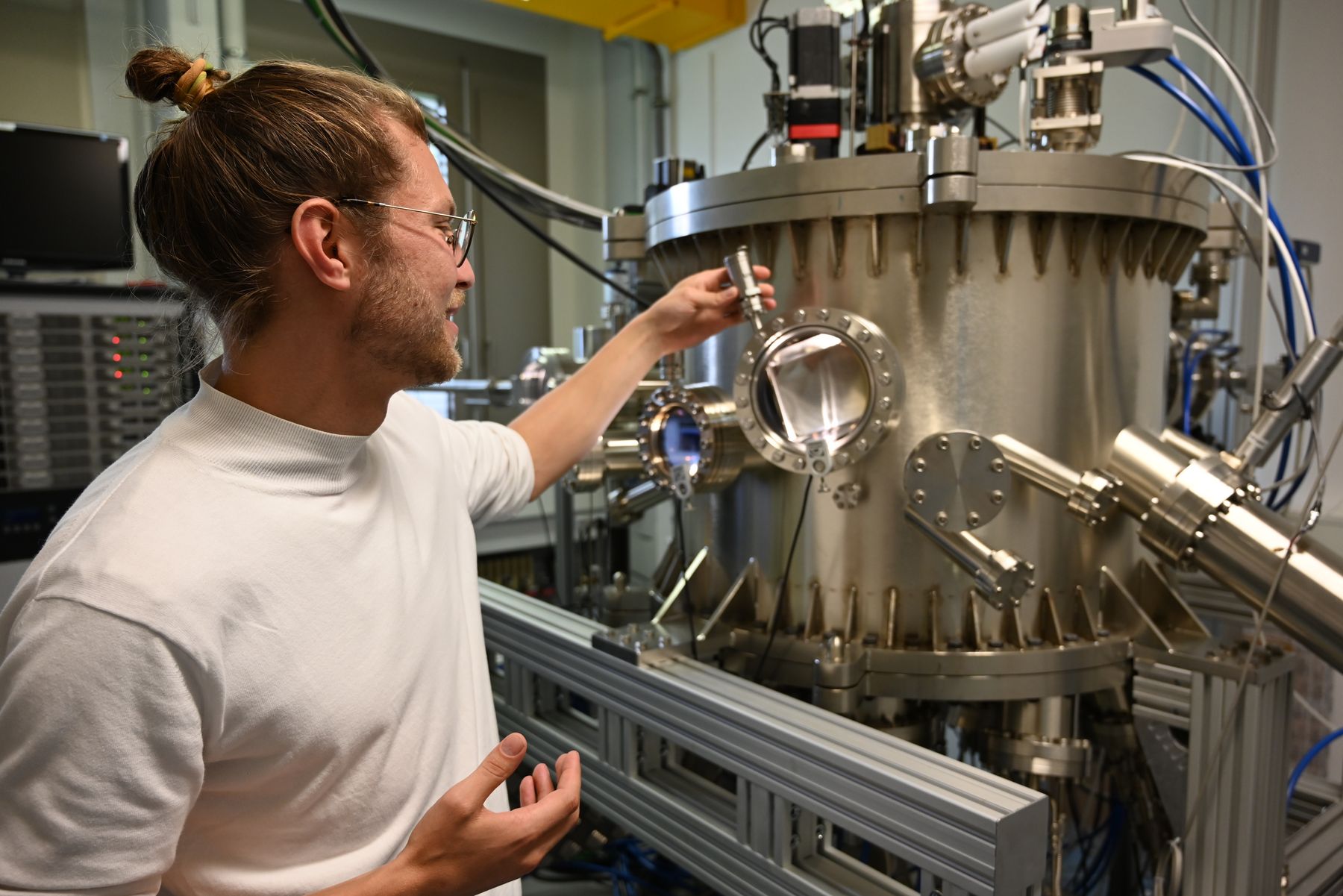

The Integration Challenge

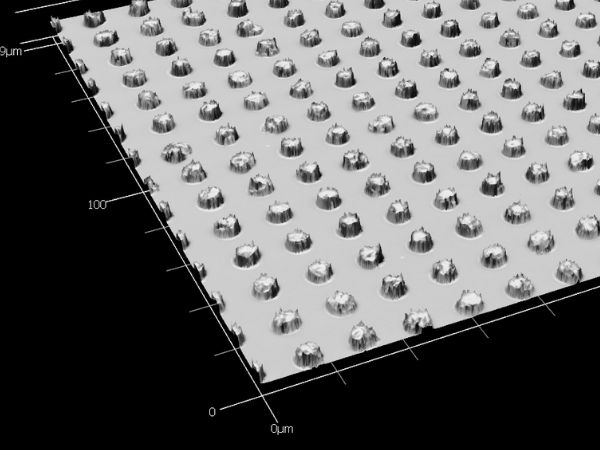

At cryogenic temperatures, precise assembly is critical — even minor misalignments can reduce the performance of the processor. Indium interconnects are ideal due to their superconducting properties, ductility, and low microwave loss, but present challenges in stability, oxidation, and scalable integration. With each qubit needing 1–2 signal lines, lateral connections alone are insufficient.

Peak Quantum addresses this with 3D stacking, vertically integrating chip layers and connecting qubits to control and readout electronics via superconducting interconnects. This enables higher qubit density, shorter signal paths, and scalable processors.

Key requirements:

- extreme alignment accuracy

- parallelism across the chip

- IBI flip-chip bonding for superconducting 3D integration

The Finetech Solution

Scaling quantum hardware demands advanced packaging with precise integration, stable routing, and cryo-robust materials. Finetech supported Peak Quantum with specialized IBI flip-chip bonding processes on the FINEPLACER® femto 2, delivering sub-micron placement accuracy and perfect co-planarity for uniform bondline thickness and high yield.

Flexible IBI processes — cold/thermal compression and oxide reduction — combined with sub-kelvin force/temperature control and a clean N₂/formic acid environment, ensure reliable superconducting connections. This accuracy and process control protects qubit coherence and enables scalable 3D integration.

Successful Scalability Paves Way for Real-World Applications

Peak Quantum has demonstrated the scalability of its superconducting QPUs with a unique error-protected qubit architecture, paving the way for cost-efficient, fault-tolerant, and application-ready quantum computing.

Building on this success, the company contributes its expertise to the EU-funded “SUPREME” pilot line, helping establish a central fabrication site in Munich focused on advanced 3D integration and superconducting chip packaging.