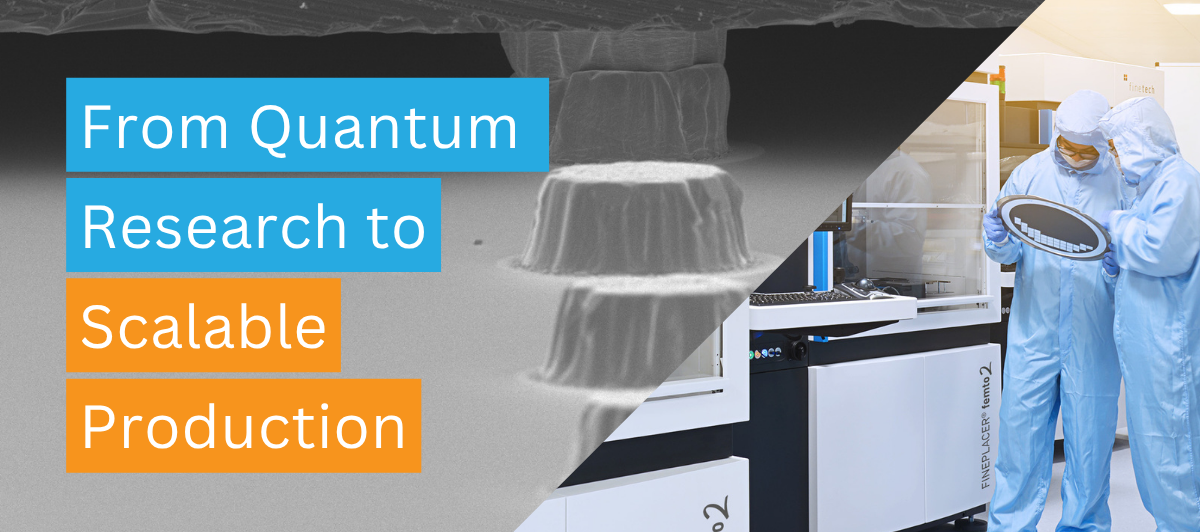

量子技術は、実験的な研究段階から商業的な実用化へと急速に移行しています。2025年現在、スケーラブルで高精度な量子ハードウェアに対する実需が急増しています。

McKinseyの「Quantum Technology Monitor」によると、以下の傾向が示されています。

- 量子コンピューティングの収益は2025年に10億ドルを超える見込みです。

- ベンチャー部門および公共部門全体で投資が加速しています。

- AI(人工知能)と量子技術が収束し、イノベーションを推進しています。

- セキュリティの確保と製造の実現可能性が最優先事項となりつつあります。

- 2035年までに、量子技術は970億ドルの収益と最大2兆ドルの産業価値を創造する可能性があります。

この技術を本格的にスケールさせるには、これまでにないレベルのボンディング精度、信頼性、およびパッケージングの柔軟性が求められます。

インテグレーションの課題

量子デバイスが生産段階へ移行するにつれて、メーカーは独自のダイボンディングの課題に直面しています。

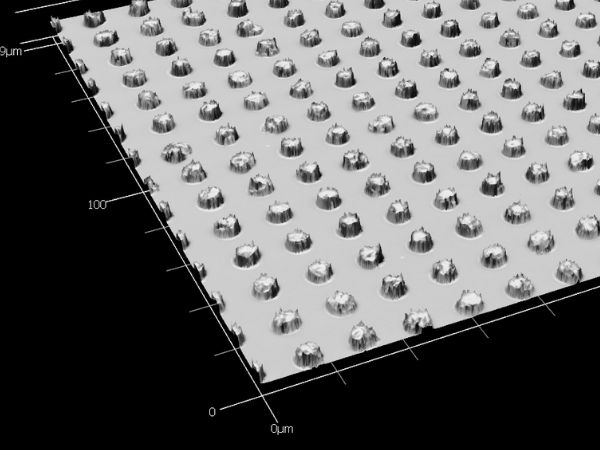

- 繊細なチップとフォトニックデバイスには、サブミクロン精度のボンディングが必要不可欠です。

- クライオジェニック(極低温)互換のインターコネクト(例:インジウムバンプ)には、厳密なプロセス制御が要求されます。

- 光学、RF(高周波)、電子機器の統合は、小型かつ欠陥のない形で実現されなければなりません。

既製のツールではもはや不十分であり、次世代の量子ハードウェアには、高度で適応性の高いプラットフォームが必要とされています。

顧客の成功事例:WMI(Walther-Meißner Institute)における超伝導キュービット

WMI(Walther-Meißner Institute)は、100個以上のキュービット(量子ビット)を持つ超伝導量子プロセッサを開発しています。これには、超精密なインジウムバンプボンディング、厳密な平坦性、そしてスケーラブルで再現性のあるプロセスが要求されます。

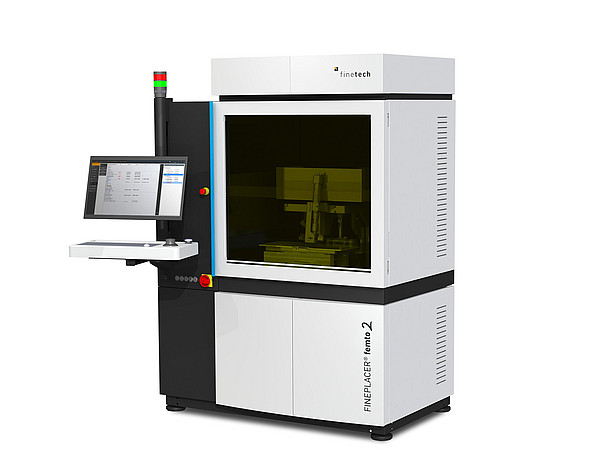

これらの要求に応えるため、WMIは自前のサンプルを用いた広範な試験の後、ファインテックの FINEPLACER® femto 2 を採用しました。このシステムは以下の点を提供しました。

- コールドコンプレッション(低温圧着)による信頼性の高いサブミクロン・インジウムバンプボンディング

- 少量多品種、高価値の量子デバイス向けの、再現性が高くクリーンなプロセス

- 進化する統合ニーズに応じてスケール可能なモジュラープラットフォーム

- 現地のテクニカルサポートとファインテックのエンジニアとの直接的な連携

このパートナーシップにより、WMIは研究試験段階から真の量産準備態勢へと移行し、将来的なチップスタッキングやファンアウトパッケージングへの基礎を築きました。(全記事はこちらからお読みいただけます。)

なぜファインテックなのか?

ファインテックは、プロトタイプから生産に至るまで、量子技術のイノベーターが自信を持ってスケールアップできるよう支援します。

- 配置精度は0.3 µm @ 3シグマまで対応

- サーモコンプレッション、共晶、インジウム、レーザーアシストなど、各種ボンディングプロセスに柔軟に対応

- プロトタイピングから量産まで対応する単一のプラットフォーム

- フォトニクス、量子、クライオジェニックパッケージングにおける30年以上の経験

フォトニック回路、トラップドイオン型プロセッサ、超伝導システムのいずれを構築する場合でも、ファインテックは、精密ボンディングをあらゆる段階でスケールさせるためのツールと専門知識を提供します。

量子技術を共に実現しましょう

量子技術は急速に進歩しており、製造もこれに遅れをとるわけにはいきません。ファインテックでは、機器を提供するだけでなく、量子技術特有の課題に対応した専門的なサポートと精密なソリューションを提供しています。

量子技術の潜在能力を、量産可能な現実へと変えるために、共に取り組んでいきましょう。