All-in-one Laser Packaging: Precision and Efficiency in One System

Our solution is designed to optimize your production efficiency and quality, reducing complexities and enhancing your operational capabilities, thereby positioning your business for success in a highly competitive landscape.

Lean on expert support throughout the entire development process, ensuring your laser packaging manufacturing reaches the market faster without compromising on quality, risks, or costs. Our comprehensive solutions streamline the process, delivering high-quality laser packages efficiently and reliably.

Are you a manufacturer involved in the 1st and 2nd level packaging? Are you facing any of these challenges? High overhead costs Dependency on external suppliers (availability, quality, specifications) Lack of precision in bonding Inefficient thermal management Cumbersome downstream processes

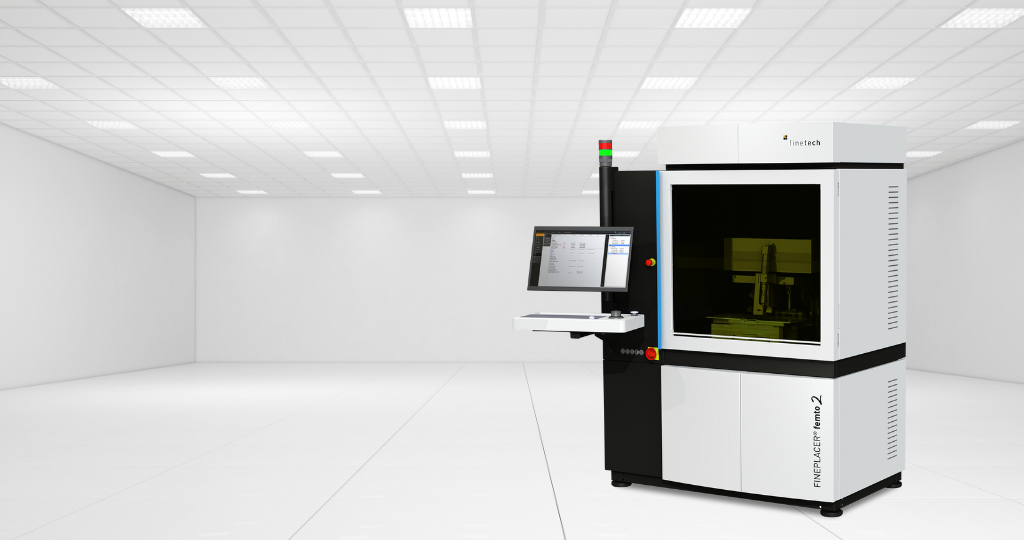

Finetech, with over 30 years of experience in laser packaging, offers a wide range of die bonders, including the FINEPLACER® femto product line. These products feature many innovative solutions for laser packaging, such as the Laser Activation Module for Reactive Multilayer Soldering (RMS), sophisticated tools for high-speed, high-precision, and high-quality laser diode soldering, and the Laser Bottom Heater for dense Chip-to-Wafer soldering/bonding, among others.

All providing an effective solution to the challenges encountered in 1st and 2nd level laser packaging.

Bringing your full packaging process into one system reduces dependencies on external vendors and tools, minimizes the need for purchasing and maintaining additional machines, optimizes assembly processes with single-system control and efficiency, and ensures precision bonding. This enhances thermal management and performance across all facets of laser bonding.

By using this element, you agree that your data will be transmitted to external services (https://www.youtube-nocookie.com) and that you have read our privacy policy.

Read our technical papers:

Pioneering Integrated Photonics Packaging with the FINEPLACER® femto 2

At PHIX, the FINEPLACER® femto 2 is used for a wide range of flip chip and die packaging tasks and its significance is best exemplified in Phix’ PHOTO-SENS project for the assembly of hybrid biosensor PICs.

We are here to help you:

Embrace the power of our fully automated FINEPLACER® femto product line to revolutionize your laser production process, significantly reducing overheads and operational costs.

This strategic move not only enhances your production efficiency but also allows you to offer more competitive pricing to your customers by eliminating the extra costs tied to outsourcing.

The benefits are twofold: you’ll see an improved return on investment thanks to decreased production expenses, and your customers will appreciate high-quality products at more affordable prices.

- Significant Cost Reduction: Transition to in-house production with our femto line to avoid the markups of outsourcing, directly translating into cost savings for your business and lower prices for your customers.

- Enhanced Competitive Edge: With the ability to offer superior products at competitive prices, you’ll position your business as a leading player in the market, ready to capture more market share and drive growth.

- Reinvestment Opportunities: The savings you achieve can be reinvested into your business, whether it’s in research and development, expanding your product line, or exploring new markets, paving the way for sustained success and innovation.

Our FINEPLACER® femto product line enhances in-house laser assembly and second-level packaging, merging them into a single, fully automated process. By leveraging our proven CoS assembly technologies, you not only simplify your production line but also significantly reduce dependencies on external vendors and multiple processes in multiple machines.

This all-in-one solution simplifies logistics and enhances manufacturing control, ensuring reliability and efficiency in every step of your production.

- Single-System Efficiency: The FINEPLACER® femto product line integrates laser assembly and packaging, eliminating the need for multiple tools, processes and machinary.

- Automation Advantage: Fully automated systems enhance production speed and consistency, reducing manual intervention.

- Streamlined Manufacturing: Simplify your production line, achieving higher throughput and lower operational complexities.

Our expertise in tooling is unmatched, designed to deliver the utmost quality across all facets of laser bonding and packaging. Whether you’re grappling with co-planarity, wettability, smile and polarization, force, overhand or accommodating diode sizes large or small, our tools are engineered to ensure your success.

What are your benefits?

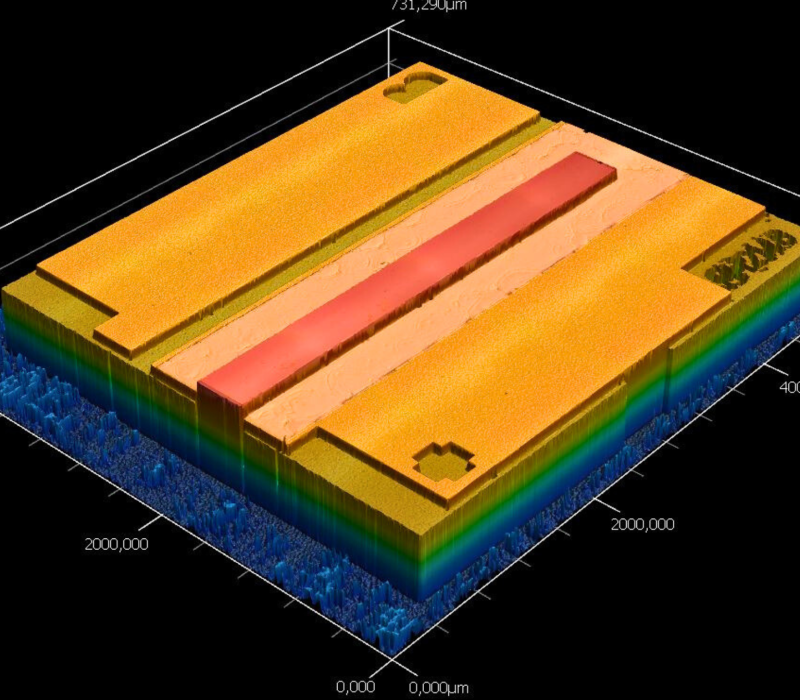

- Best eutectic soldering with precision alignment: Build perfect CoS and avoid catastrophic failure through perfect thermal conductivity by soldering management and perfect overhang alignment.

- Maintaining and controlling superior beam quality of laser diodes: Next generation laser tools for lowest possible stress while eutectic soldering for best repeatability in polarization and minimal wavelength shift.

- Precision in Every Aspect: From achieving perfect co-planarity and wettability to applying the right force, we make no compromises in ensuring your lasers are bonded with unmatched precision.

Our meticulous approach to the bonding process ensures that every aspect of the laser chip’s interaction with the substrate — from the bond line to surface contact and overhang — is optimized for maximum heat dissipation.

This precision in assembly not only enhances the reliability of your lasers in demanding operational environments but also significantly extends their lifespan while minimizing the need for maintenance.

- Precision Bonding for Enhanced Reliability: Our advanced bonding techniques ensure perfect alignment and contact, crucial for optimal thermal management and consistent performance under all conditions.

- Long-Term Cost Efficiency: The improved thermal handling capacity of our bonded laser systems leads to longer operational lifespans and lower maintenance requirements, translating into significant savings over time.

- Unwavering Performance in Demanding Environments: Trust our bonding solutions to maintain your laser’s efficiency and reliability, even in the most challenging operational scenarios, ensuring your applications run smoothly and without interruption.

Package densely populated components onto substates or wafers using our Laser Substrate Heater module

Finetech’s Laser Substrate Heater module enhances chip-to-substrate and chip-to-wafer assembly by delivering precise, localized heating for faster, more accurate processes. This method minimizes oxidation risks through rapid temperature cycles and does not require complex thermal expansion precautions.

Ideal for high-accuracy soldering, the technology uses an IR laser to efficiently heat components, reducing process time and eliminating the need for protective atmospheres during soldering. With its ability to process multiple substrates sequentially without transferring to a heating plate, Finetech’s solution offers streamlined production and superior assembly quality in electronic manufacturing.

Meet our FINEPLACER® femto systems

FINEPLACER® femto pro

The Efficient Solution for Advanced Packaging

An automated die bonder with placement accuracy of 2 µm @ 3 Sigma and bonding forces up to 1,000 N.

FINEPLACER® femto 2

Advanced Automated Sub-Micron Bonder

Fully-automated die bonder offers unrivaled flexibility for prototyping & production environments.

The modular design of the automated die bonder FINEPLACER® femto 2 can be individually configured and retrofitted at any time to support new applications and technologies.